product

contact

phone:021-33674800 /18019714807

fax:021-33674801

post box:info@sealtex.cn

Raw materials

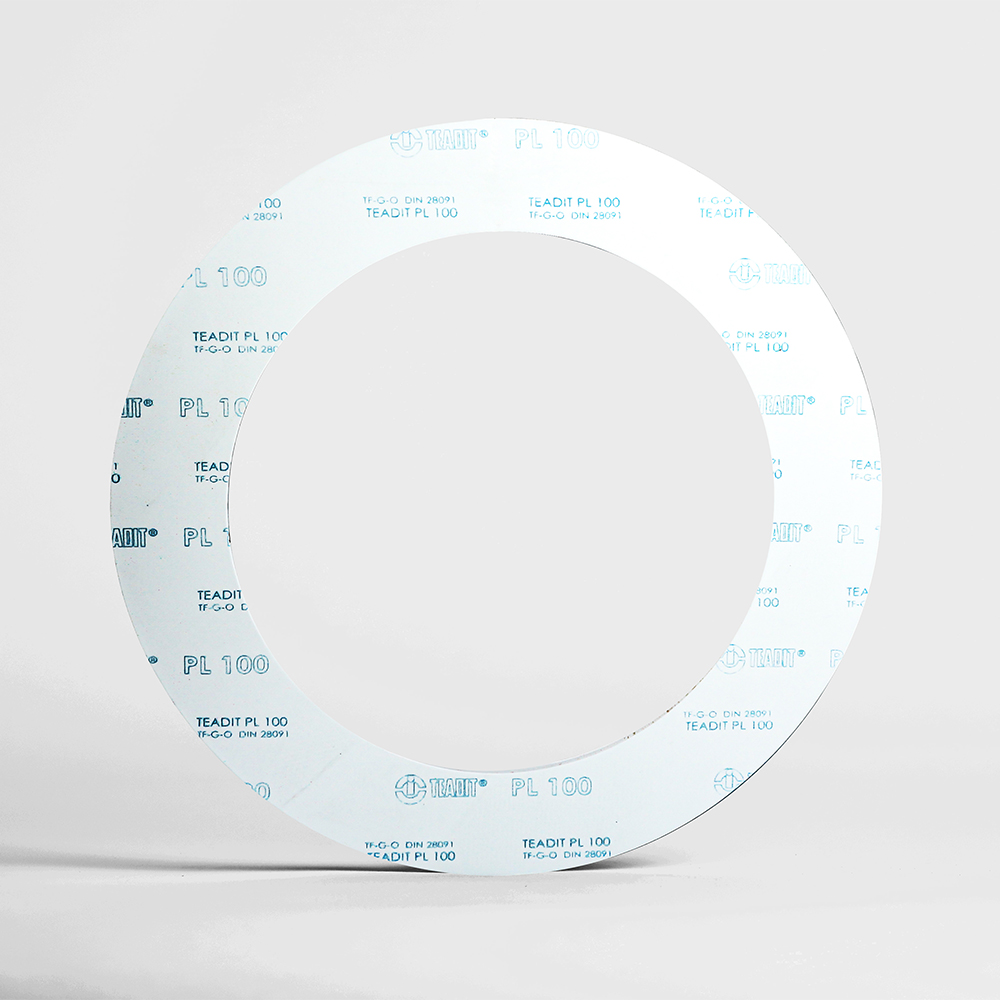

TEADIT PL100

TEADIT PL100

Applications and Benefits

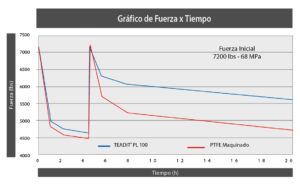

TEADIT® PL 100 is a highly compressible sheet, manufactured with PTFE through a unique lamination process, with a high level of fibrillation, which provides reduced loss of tightness and fluidity, inherent deficiencies of the existing machined (rigid) sheets in the market, being also used in contact with food and pharmaceutical products. It has excellent dimensional stability, torque retention and the best cost-benefit ratio among similar materials. Due to the chemical properties of PTFE, TEADIT® PL 100 is suitable for sealing a wide variety of chemically aggressive fluids. The manufacturing process of TEADIT® PL 100 produces a rigid, low density sheet, which facilitates the manufacture of light and structured gaskets, allowing its installation even in places of difficult access and with little space for the opening of the flanges. Its high compressibility also enables TEADIT® PL 100 gaskets to be used on flanges or irregular surfaces. Their non-stick properties make it easy to remove the gaskets after use, even without leaving any material residue on the flanges.

Technical Data

Operating Parameters TEADIT® PL100

Maximum temperature (℃) 260

Minimum temperature (℃) -268

Maximum pressure (bar) 55

pH 0-14

Pressure x Temperature bar x ℃

Thickness of 1.5 mm 12,000

Thickness of 3.0 mm 8,600

Supply 1,500 x 1,500 mm plates

Thicknesses 1.5, 2.0 and 3.0 mm (others on request)