Technical

-

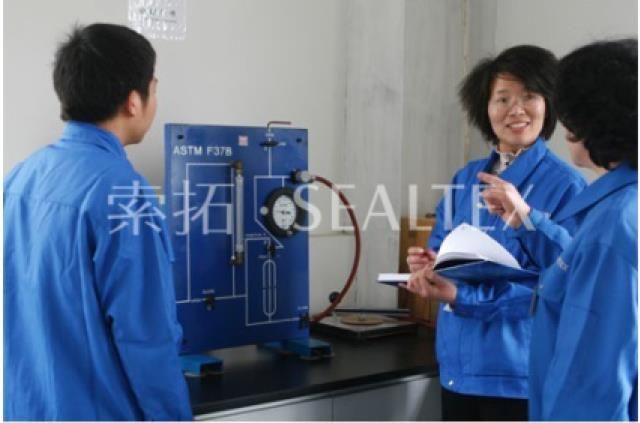

With professional technicians and advanced testing instruments as well as well-equipped laboratory and stern operation procedure, we guarantee and satisfy our customers with the most proper and accurate data in terms of products in various industrial conditions.

-

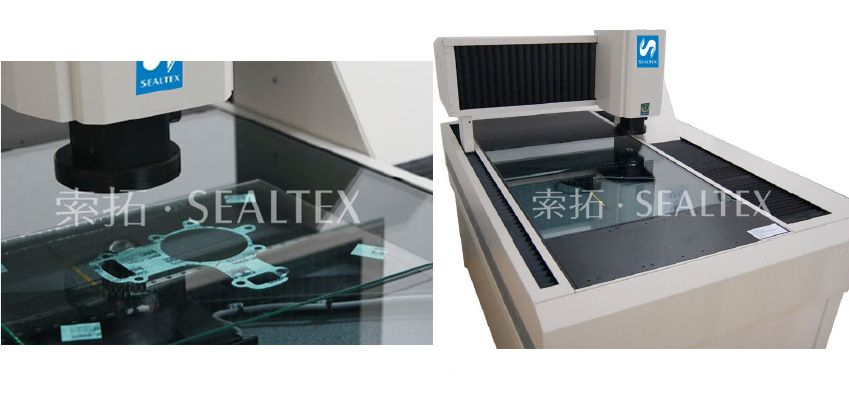

Owning the presently-most-advanced testing instrument, the 3-D non-contact optical measuring instrument, we’re able to instantly figure out accurate specifications of various moulds and gasket products.

The 3-D non-contact optical measuring instrument employs new technologies to provide high speed and accuracy on reliable and affordable measurement systems. The gantry style vision system can accommodate large parts and fixtures of multiple parts while maintaining a relatively small footprint. “Monorail” linear way bearings, dual encoder servo control, and sophisticated electronics allow these systems to reach 20 in/sec. With the advanced lighting, zoom control, and edge detection tools included in the latest InSpec Vision Metrology Software. This instrument can handle the most demanding measurement applications.

-

Besides, we have been equipped with instruments such as Tensile testing machine, Compression and recovery detector, Muffle furnace ect for testing of strength, compression, thermal-withstand, Anti-creep capability etc.

To ensure and guarantee a high efficiency and accuracy, our lab has some other standard instruments too