product

contact

site:Room 502, building 23, no. 487 tianlin road, xuhui district, Shanghai

phone:021-33674800 /18019714807

fax:021-33674801

post box:info@sealtex.cn

phone:021-33674800 /18019714807

fax:021-33674801

post box:info@sealtex.cn

Raw materials

current position | home page > Raw materials > teflon

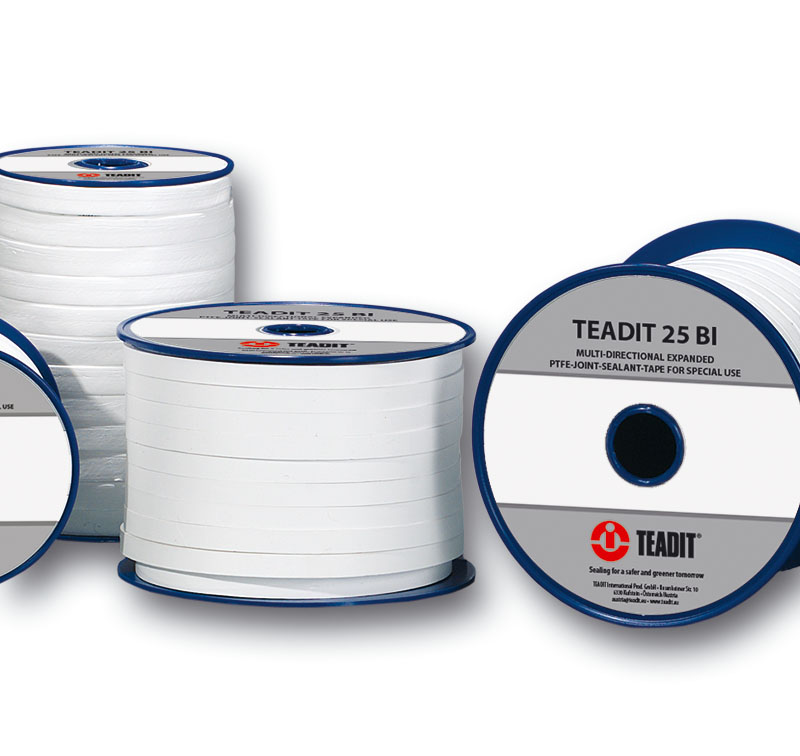

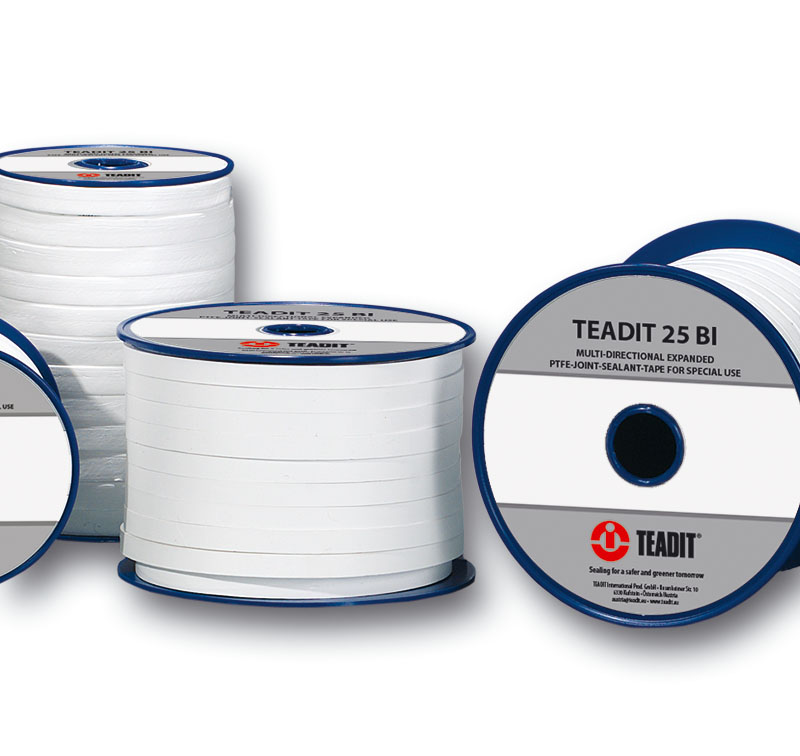

TEADIT 25BI

Description:

TEADIT 25 BI is a multidirectionally expanded gasket-tape,

produced from 100 % pure PTFE (Polytetrafluorethylen).

TEADIT maintains a quality and environmental management

system that is certified according to DIN EN ISO 9001 and DIN

EN ISO 14001.

Application areas:

TEADIT 25 BI – due to its excellent malleability – is particularly

well suited to compensate for irregularities or damages on the

sealing areas, as well as for all stress-sensitive joints.

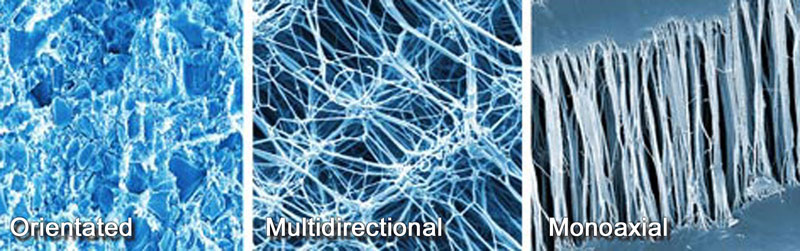

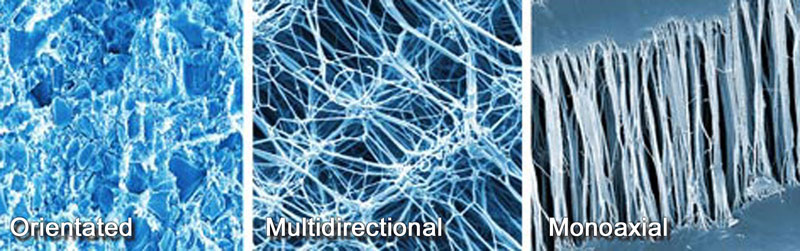

A special manufacturing process results in almost equal tensile

strength in both the longitudinal and cross direction. As a result

of this, the material does not change its width under

compression. This is in stark contrast to normal expanded PTFE

tapes!

TEADIT 25 BI, because of this property, is extremely well suited

as a gasket material for narrow sealing areas and in all

applications where a defined gasket width (under load) is

required. Typical applications are enamelled and glass flanges,

heat exchangers, large flanges and containers, pressure vessels,

suction filters and strainers, etc.

Technical data:

• PTFE Temperature range: -268 °C to +260 °C

(short time +315 °C)

• Chemical resistance: chemically inert against most substances

(pH 0 – 14), including the most aggressive acids and lyes. The

only exceptions are molten alkali metals and elemental fluorine

at high temperatures and high pressure

• Ageing: TEADIT 25 BI does not age and can be stored

indefinitely. (Please note: the adhesive tape has limited shelf life)

• Minimum stress to seal Qmin/L (EN 13555 HE, 40 bar)*

L[mg/s*m] 10ˉ² Qmin/L [MPa] = 23

L[mg/s*m] 10ˉ³ Qmin/L [MPa] = 31

* tested with 2.0mm thickness

• Recovery (ASTM F36): 10 %

• Compressibility (ASTM F36): 70 %

Typical application range:

• Temperature range: -60 °C up to +230 °C

• Operating pressure: from vacuum to 40 bar

For details on applications with higher temperatures and /

or pressure please contact TEADIT application engineering!

Tests & Approvals:

• FDA & EC 1935/2004 & EU 10/2011 (all incl. adhesive)

• TA-Luft

TEADIT 25 BI is a multidirectionally expanded gasket-tape,

produced from 100 % pure PTFE (Polytetrafluorethylen).

TEADIT maintains a quality and environmental management

system that is certified according to DIN EN ISO 9001 and DIN

EN ISO 14001.

Application areas:

TEADIT 25 BI – due to its excellent malleability – is particularly

well suited to compensate for irregularities or damages on the

sealing areas, as well as for all stress-sensitive joints.

A special manufacturing process results in almost equal tensile

strength in both the longitudinal and cross direction. As a result

of this, the material does not change its width under

compression. This is in stark contrast to normal expanded PTFE

tapes!

TEADIT 25 BI, because of this property, is extremely well suited

as a gasket material for narrow sealing areas and in all

applications where a defined gasket width (under load) is

required. Typical applications are enamelled and glass flanges,

heat exchangers, large flanges and containers, pressure vessels,

suction filters and strainers, etc.

Technical data:

• PTFE Temperature range: -268 °C to +260 °C

(short time +315 °C)

• Chemical resistance: chemically inert against most substances

(pH 0 – 14), including the most aggressive acids and lyes. The

only exceptions are molten alkali metals and elemental fluorine

at high temperatures and high pressure

• Ageing: TEADIT 25 BI does not age and can be stored

indefinitely. (Please note: the adhesive tape has limited shelf life)

• Minimum stress to seal Qmin/L (EN 13555 HE, 40 bar)*

L[mg/s*m] 10ˉ² Qmin/L [MPa] = 23

L[mg/s*m] 10ˉ³ Qmin/L [MPa] = 31

* tested with 2.0mm thickness

• Recovery (ASTM F36): 10 %

• Compressibility (ASTM F36): 70 %

Typical application range:

• Temperature range: -60 °C up to +230 °C

• Operating pressure: from vacuum to 40 bar

For details on applications with higher temperatures and /

or pressure please contact TEADIT application engineering!

Tests & Approvals:

• FDA & EC 1935/2004 & EU 10/2011 (all incl. adhesive)

• TA-Luft

• WRAS

Advantages:

• quick and simple installation, no cutting or punching

necessary

• the used gasket can be easily removed without leaving

any deposits on the sealing areas

• excellent malleability makes the repair of minor

damages and irregularities unnecessary

• extremely versatile because of exceptionally good

chemical and thermal stability

• there is less danger of choosing the wrong gasket

material because TEADIT 25 BI can be used for most

applications within the plant

• longer gasket life (less downtime)

• no material waste

• low stock cost