product

contact

phone:021-33674800 /18019714807

fax:021-33674801

post box:info@sealtex.cn

Raw materials

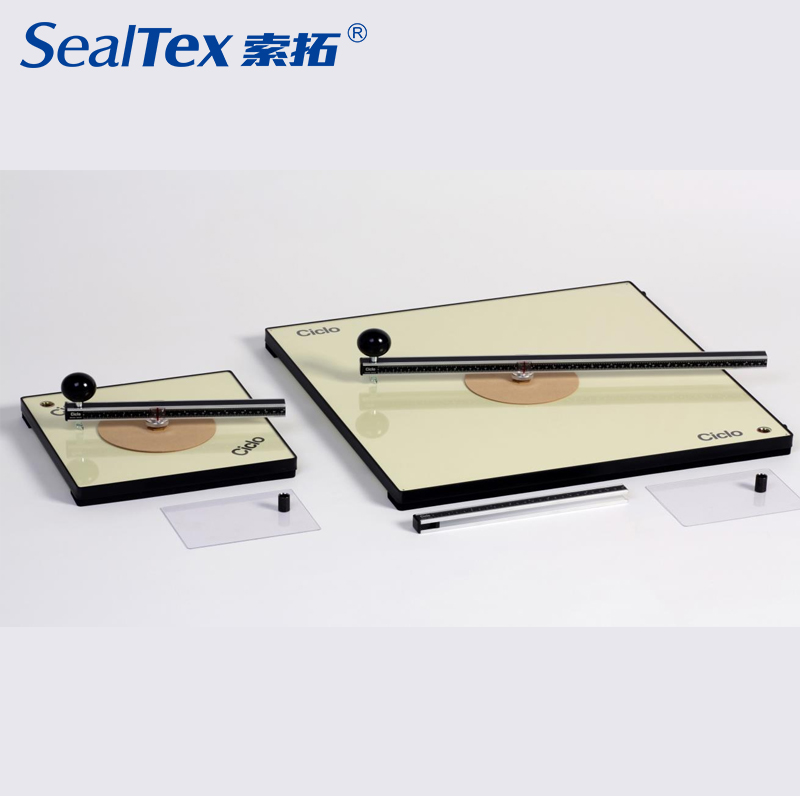

Ciclo Circular Cutter

Ciclo Circular Cutter

For cutting of flat gaskets made of any materials up to 12mm thickness and diameters from 30 up to 1000mm available in two sizes.

ART-3027 for :from centre 30 up to 270mm ,from corner 270 up to 500mm

ART-3050 for:from centre 30 up to 500mm ,from corner 500 up to 1000mm

OperationManual:

1. Place board on a table or better still, grip the clamping block in a vice.

2. Punch a central hole in the gasket material.

3. Hold the gasket by the clamping bush screwed into the appropriate position on the board through the punched hole and tighten by turning the material.

4. Adjust the cutting arm length by lining up the desired radius and the red line. (Remember, firs o.d., then i.d.).

5. Insert pivot pin fully into clamping bush.

6. Turn clockwise, pressing lightly depending on the type of material, always turn horizontally.

Description:

• The blade is a universal cutter made of hard metal alloy but will not resist hard knocks. A spare cutting edge is to be found on the opposite end.

• Various spare parts available.

• The central hole is best pressed into the gasket material, rather than punched.

• Old material should be washed and to be cut when still wet. Make sure, material lies flat

• Thin material tends to wrinkle, use adhesive tape on edges of base board.

• Thick, hard or tough sheets should be cut from both sides.

• Reinforced material of fine texture can be cut with ease, but coarse reinforcing will tend to break the blade. Steel foil however, can be easily be cut with some practice.

• The hollow ground punch with inside cut prevents the cracking of hard material, but for normal gasket material, any 14mm hollow punch will be found suitable.

• The cutting plate, when worn, can be reversed or replaced. (Pull out and insert fresh plate by pressing into place).

• Trouble shooting guide: The cut is irregular = seating ring is loose. Depth of cut is not even = flange nut is not fitted correctly or the cutter shaft is running too tight. Cuts from both sides do not correspond = the central hole is too large.