Small Engine sealing

|

1、Intake/Carburetor(Air/Fuel) 2、Carburetor/Spacers(Air/Fuel) 3、Air Cleaner/Carburetor(Air/Fuel) 4、Crankcase(Oil) 5、Cylinder Head(Oil) 6、Rocker Cover(Oil) 7、Heat Shields(Hot Air) 8、Exhaust(Hot Air) |

| Material Recommendations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*Material will need be combined with metal reinforcement |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

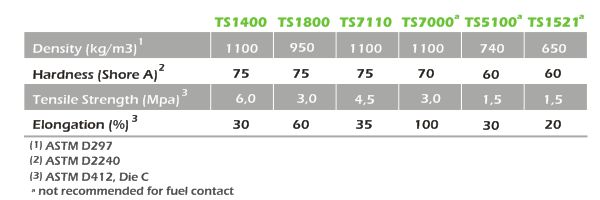

| Specification | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1、Air cleaner gasket 2、Carburetor gasket 3、Intake gasket 4、Valve cover gasket 5、Breather gasket 6、Breather passage gasket 7、Crankcase gasket |

·Tolerance to extreme surface finishing conditions, such as "ascast"

Characteristics & Advantages

·Conformable to flanges with higher "out-of-flatness" values, such as stamped steel and plastic covers .

·Lower bolt torques possible.

·Fewer fasteners in the system.

·Smaller or lower grade fasteners.

·Components with less mass and more distortion

·Stable damping values across the frequency range reducing vibrations effectively

·Easy to fabricate